Developed in the 1890’s by the French scientist A. Verneuil, this is one of the first methods used to produce synthetic gemstones, initially for corundum, thereafter for a number of other gemstones.

How gemstones are synthesized by flame fusion process?

This method is based on the melting of very finely pulverized alumina in an oxy-hydrogen blowpipe type burner. This requires a highly purified alumina which is prepared by repeated crystallization and later calcination of ammonium alum.

- The alumina is placed in a container or hopper which is tapped from above by a hammer at regular pre-selected intervals and regulates the flow of powder.

- This powder drops through the oxy-hydrogen flame, melts and falls on a rotating pedestal, where it solidifies.

- This pedestal is lowered slowly to allow cooling and crystallization of the corundum boule.

- The flame temperature generally ranges from about 1000°C to 2400°C since the melting point of corundum is approximately 2050°C.

- Both the growing crystal and the flame are protected from temperature variations by a circular ceramic heat resistant walled area.

- Boules are generally up to twelve inches, in size.

- The different varieties of corundum are obtained by adding various metallic oxides to the alum before it is calcined. Examples:

Ruby 1% to 2% chromium oxide Dark brownish red ruby chromium oxide + iron oxide Blue sapphire 2% iron oxide + 1% titanium oxide Yellow sapphire iron oxide + nickel oxide + uranium oxide + titanium oxide + thallium oxide Purple / violet sapphire iron oxide + chromium oxide + titanium oxide

The one major disadvantage of this method is that a great deal of internal strain is developed as a result of which there is a tendency for the stone to crack.

Gemstones synthesized by flame fusion with its identification.

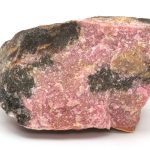

- Synthetic corundum (synthetic ruby, synthetic sapphire (all colours) synthetic star ruby, synthetic star sapphire)

- Synthetic corundum has similar physical and optical properties as the natural counterparts.

- Under magnification – Gas bubbles, curved lines, curved colour bands in synthetic blue sapphire, unmelted powder in various forms are seen.

- Synthetic star stones (Linde) contain fine silk at the surface along with gas bubbles and curved lines / bands.

- Plato lines in light coloured corundum. (This is seen when the stone is immersed in methylene iodide liquid and observed along the optic axis direction using cross polarised light. Dark lines appear at angles to the optic axis direction along the polysynthetic twinning planes in the crystal).

- Some varieties give a chalky fluorescence under short wave ultra violet light.

- Synthetic Spinel:

- All colours except red

- Synthetic spinel in general is synthesized with higher aluminium content and as a result generally exhibits A.D.R. (S.R.) reaction under the polariscope.

- The R.I. is 1.73 +

- The S.G. is 3.64

- Spectrums as per the colour.

- Synthetic red spinel boules tend to crack due to the internal strain and are therefore not commonly synthesized by this method.

- Synthetic Rutile:

- Various colours.

- Yellowish body colour is common.

- Highly birefringent stone – D.R. 0.287, strong doubling.

- High dispersion of 0.290

- The S.G. is 4.20

- Gas bubbles under magnification.

- Strontium Titanate:

- In all colors.

- Colourless when pure, without any dopants, – diamond simulant.

- Isotropic character.

- The S.G. is 5.13

- High dispersion of 0.190

- Gas bubbles under magnification.

Leave a Reply

You must be logged in to post a comment.