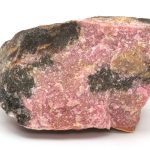

Extraction of Rough Gemstones from the Ores

The process of extracting the gemstones from the ores varies from place to place and is dependent on the nature and quality of the gemstone. In general those from alluvial deposits are assorted by washing with sieves.

- Slurry containing the gemstone rough along with mud and other materials is washed with water on a sieve. A vibratory motion is applied to the sieve so as to separate the slurry quicker. The gem rough is then hand picked from the sieves. Depending on the size of the rough, different sieve sizes are employed. This method is commonly employed for most gemstones.

Extraction of Rough Diamonds from the Ores

In the case of Diamond extraction from the mother rock, the process is more complicated. The entire process however utilises the properties of diamonds to separate them. Following are the basic processes by which diamonds are recovered from the ore.

- Crushing: Done to reduce the size of the rocks in the ore.

- Heavy Media Separators: Make use of the property of specific gravity wherein a heavy stone will sink in a liquid of lower specific gravity. Either one or a series of Heavy Media Separators are used to separate the diamonds. A centrifugal force is applied to the liquid inside, for faster separation.

- Grease Table or Belt: Uses the property that diamonds stick to grease. The ore is poured over this table and washed with water. A vibratory motion is given to the table. The diamonds with a few other minerals stick to the table while the rest is washed off. Heat is used to separate the diamonds from the grease.

- X – Ray Separators: Uses the principle that diamonds fluoresce to X – rays. The ore is dropped in a fine stream through a channel and an X- ray beam is directed at it. As a diamond fluoresces, a detector activates an airjet and the diamond is directed into another channel.

- Magnetic Separators: In areas where there are magnetic minerals present in the ore, a magnetic belt is used for separation.

The material which is discarded, also known as tailings, after going through the processes in a treatment plant is sometimes re-checked and is considered in the evaluation of the efficiency of the plant. The diamonds which have been separated are now washed in acid and cleaned, ready for assortment. Diamonds which are coated will probably not react well to the above processes. Under the circumstances, the quality of the rough should be ascertained before the specific processes are employed.

Leave a Reply

You must be logged in to post a comment.