The process is used to synthesize synthetic moissanite, comparatively a newer and best diamond simulant after synthetic diamonds. Synthetic moissanite was launched in the market in 1997 by C3 Inc. Initially synthetic moissanite was available in colorless to near colorless shades, but now fancy colored synthetic moissanites are also being developed.

How synthetic moissanite is manufactured?

- In the process, feed material (silicon carbide) vaporizes and recrystallizes on the seed crystal without being passing through the liquid stage.

- Feed material is placed in one part of the crucible that dissolves on heating, and diffuses through the graphite and gets deposit on the seed crystal.

- The exact details of the process have not been released.

Identification of synthetic moissanite:

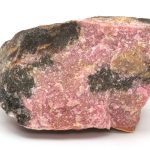

- Colourless, Yellow, Green, Pink, Brown

- Strong doubling, reflecting needles parallel to optic axis and crystals (hexagonal).

- Strong dispersion of 0.105.

- Moissanite tester being introduced by C3 Inc. for separating diamond from moissanite, may be misleading, room temperature affects the results.

- Thermal probe used for diamonds cannot differentiate moissanite because of high thermal conductivity.

Leave a Reply

You must be logged in to post a comment.