This process was perfected in USSR specifically for crystallizing synthetic cubic zirconia, for uses in optical, electronic and laser equipment. Cubic zirconium oxide has a very high melting point and is a very reactive material. No container can hold this melt since cubic zirconia has a melting point of 2750°C, and hence a cold crucible or skull is used.

How gemstones are synthesized by skull melting process?

- A container is filled with powdered zirconia, stabilizer and some pieces of zirconium metal.

- These are rapidly heated by a radio frequency field (similar to a microwave oven).

- The zirconium oxide powder is used as its own insulation and container as the temperature at the core is raised to extreme levels.

- The metal reacts with the oxygen and melts, with the exception of a skin of about 1/15 inches thick at the outside, which is kept solid by contact with the liquid – cooled copper tubes around – the skull.

- Zirconia and the stabilizer contents are kept molten for several hours to provide uniformity.

- The power is reduced and the skull is slowly lowered out of the coil.

- Crystal growth begins at the bottom of the skull and columnar crystals grow upwards until the entire melt solidifies.

- The individual single crystal columns that are readily available are generally 2 inches in diameter.

- Light tapping will separate the crystal columns.

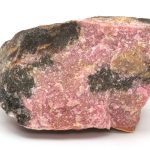

- Dopants are used to produce various colours.

Identification:

- Colourless when pure (without any dopants) – diamond simulant.

- The S.G. ranges from 5.60 to 6.20 (as per dopants used)

- Isotropic character.

- The dispersion is 0.060

- Some varieties exhibit a strong yellow fluorescence under ultra violet light.

- The characteristic inclusions seen are negative crystals, streams of zirconium oxide powder which appear as tiny white spherical bubbles.

Leave a Reply

You must be logged in to post a comment.